Prismatic Cell Manufacturing: Key Insights and Processes

Prismatic cell manufacturing involves the production of prismatic lithium-ion cells, which are characterized by their rectangular or box-like shape. This design offers advantages in space efficiency and energy density, making prismatic cells popular in electric vehicles (EVs), consumer electronics, and energy storage systems.

● Key Processes in Prismatic Cell Manufacturing

1. Material Preparation

- Active Material Mixing: Precursors for the anode (typically graphite) and cathode (lithium compounds) are mixed with binders and conductive additives to form slurries.

- Separator Production: Separators made from materials like polyethylene or polypropylene are produced to prevent short circuits between the electrodes.

2. Electrode Fabrication

- Coating: The slurry is uniformly coated onto aluminum (for cathodes) and copper (for anodes) foils using precision coating machines.

- Drying: Coated electrodes are dried to remove solvents, ensuring optimal performance characteristics.

- Calendering: The dried electrodes are compressed to enhance density, which improves electrical conductivity.

3. Electrode Cutting

- The electrodes are cut into specific dimensions tailored for the prismatic cell design.

4. Cell Assembly

- Layer Stacking: The anode, separator, and cathode are stacked together in the specified order.

- Electrolyte Filling: The electrolyte is injected into the assembly to saturate the electrodes and facilitate ion movement.

- Sealing: The assembly is sealed in a prismatic metal or polymer casing to prevent leakage and contamination.

5. Formation and Aging

- Formation Cycling: Cells undergo initial charge and discharge cycles to activate the materials, stabilizing performance.

- Aging: Cells are aged in controlled environments to ensure consistent long-term performance.

6. Testing and Quality Control

- Performance Testing: Each cell is evaluated for capacity, voltage, internal resistance, and cycle life to ensure they meet specifications.

- Safety Testing: Rigorous tests for thermal stability, overcharging, and short-circuit resistance are performed to ensure safety standards are met.

7. Packaging and Shipping

- Approved cells are packaged for shipment to customers or integration into battery packs.

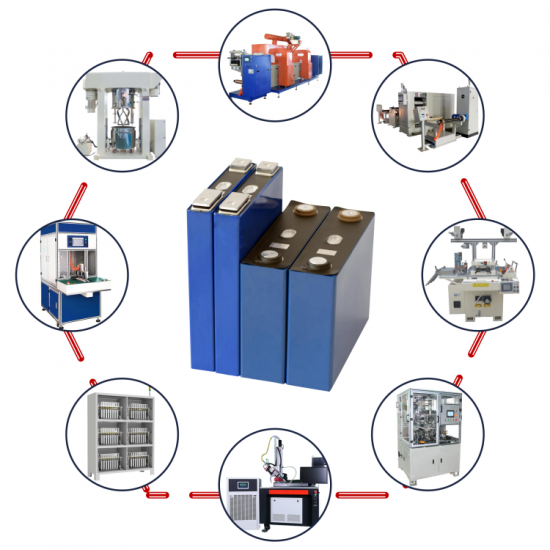

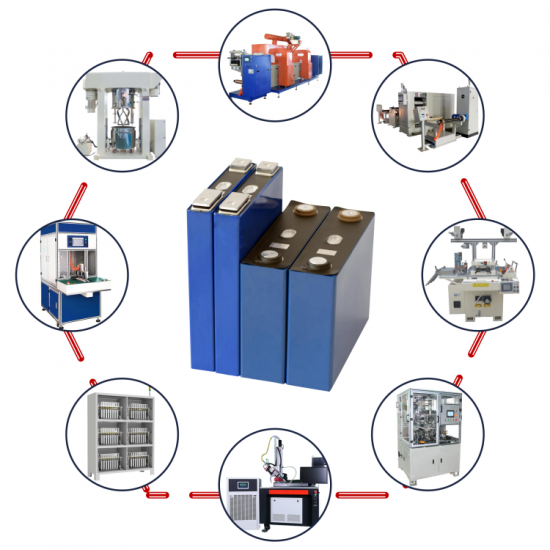

● Key Equipment in Prismatic Cell Manufacturing

1. Mixers: For preparing electrode slurries.

2. Coating Machines: For applying the active material onto foils.

3. Drying Ovens: To remove solvents from coated electrodes.

4. Calendering Machines: For compressing and improving electrode density.

5. Cutting Machines: For sizing electrodes to specification.

6. Assembly Equipment: For stacking electrodes and separators.

7. Filling Machines: For injecting the electrolyte into the cell.

8. Sealing Equipment: To secure the cell casing.

9. Testing Equipment: For performance and safety evaluations.

● Advantages of Prismatic Cells

1. Space Efficiency: Prismatic cells can be packed tightly in battery modules, optimizing space utilization.

2. Higher Energy Density: The design allows for more active material, enhancing the overall energy density of the battery.

3. Thermal Management: The flat design facilitates effective heat dissipation, improving safety and performance.

4. Scalability: Production lines for prismatic cells can be scaled to meet increasing demands in the EV and energy storage markets.

● Applications of Prismatic Cells

- Electric Vehicles (EVs): Widely used in battery packs due to their efficiency and space-saving design.

- Consumer Electronics: Found in laptops, tablets, and smartphones, where size and energy density are critical.

- Energy Storage Systems: Employed in grid storage solutions, solar energy systems, and backup power applications.

● Conclusion

Prismatic cell manufacturing plays a vital role in the production of efficient and reliable battery systems for various applications. As the demand for high-performance batteries continues to rise, advancements in manufacturing technologies and processes will be essential in meeting global energy storage needs. The ability to produce prismatic cells at scale, with a focus on quality and safety, will be crucial in supporting the transition to sustainable energy solutions.

ko

ko en

en fr

fr de

de ru

ru es

es pt

pt tr

tr pl

pl th

th

IPv6 네트워크 지원

IPv6 네트워크 지원