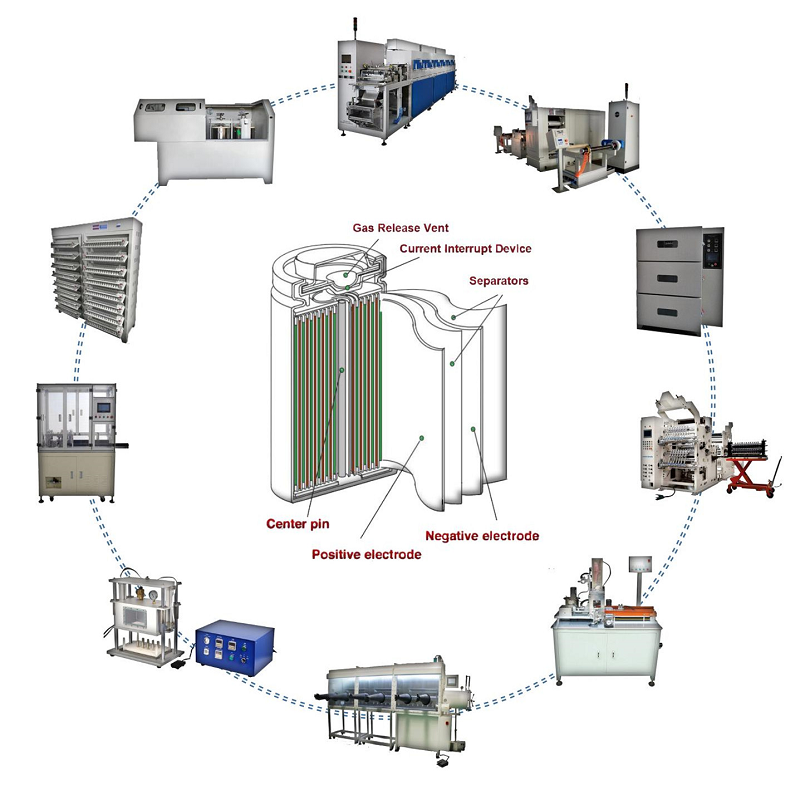

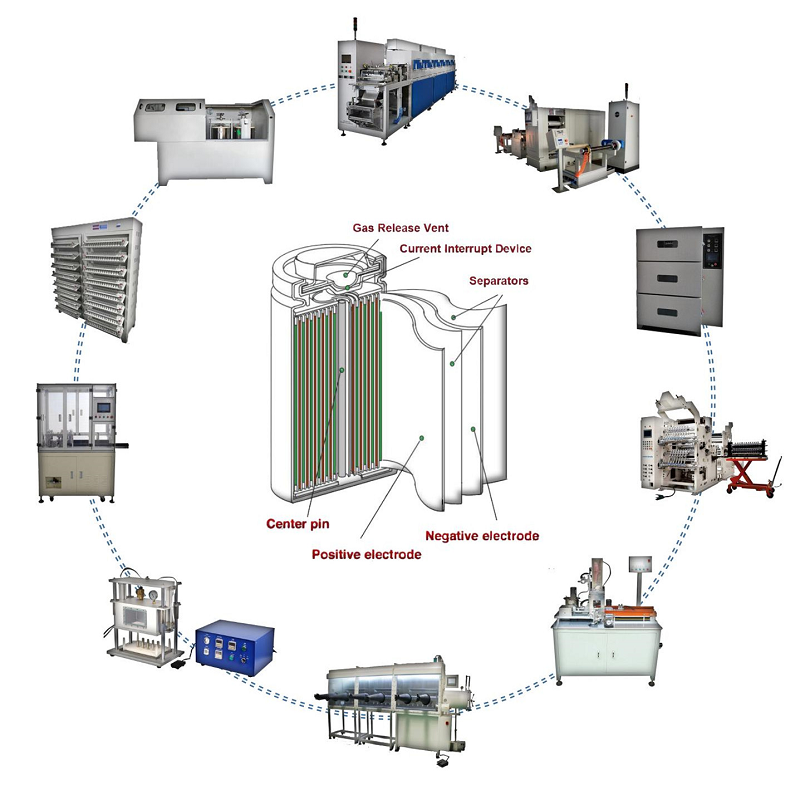

ylindrical Cell Pilot Equipment: Advancing Battery Technology

Cylindrical Cell Pilot Equipment is a suite of specialized tools designed for the research and small-scale production of cylindrical lithium-ion batteries. Comprising various components, these machines play a pivotal role in exploring innovative battery technologies and validating manufacturing processes. Below are key components commonly found in Cylindrical Cell Pilot Equipment:

Electrode Coating System:

This system uniformly applies electrode materials, including cathode and anode, onto current collectors. The uniformity of coating directly influences battery performance.

Pressing and Forming Equipment:

After electrode coating, the electrodes undergo pressing and forming processes to achieve the desired thickness and shape, ensuring proper battery functionality.

Electrolyte Injection System:

Electrolyte, a critical component in liquid form, is accurately injected into the battery through a dedicated system, ensuring precise electrolyte composition.

Battery Assembly System:

Responsible for assembling various components, such as electrodes, separators, and current collectors, the battery assembly system forms a complete battery cell.

Encapsulation and Sealing Systems:

To ensure battery stability and safety, encapsulation and sealing systems securely enclose the battery in a protective casing.

Battery Charge/Discharge Testing System:

Throughout different stages of production, Cylindrical Cell Pilot Equipment often includes systems for charge/discharge testing. This evaluates battery performance, cycle life, and other critical parameters.

Data Acquisition and Analysis Systems:

Advanced equipment integrates data acquisition and analysis systems to monitor key metrics during the battery manufacturing process. This aids in real-time insights, process optimization, and quality control.

Automation and Robotic Technologies:

Automation and robotics are frequently integrated to enhance efficiency and precision. These technologies handle component handling and transportation, reducing manual intervention.

Scalability:

Cylindrical Cell Pilot Equipment is designed with scalability in mind to accommodate varying production volumes. This flexibility is crucial for meeting diverse market demands and adjusting production levels as needed.

Quality Control and Safety Systems:

Robust quality control and safety systems are integral to Cylindrical Cell Production. These include automated inspections, safety sensors, and emergency shutdown systems to ensure both quality and safety throughout production.

In summary, Cylindrical Cell Pilot Equipment serves as a versatile tool for both research and small-scale production, supporting innovation in lithium-ion battery technology. The integration of these components facilitates the exploration of new concepts, materials, and processes, contributing to advancements in battery performance and the future development of energy storage solutions.

ko

ko en

en fr

fr de

de ru

ru es

es pt

pt tr

tr pl

pl th

th

IPv6 네트워크 지원

IPv6 네트워크 지원