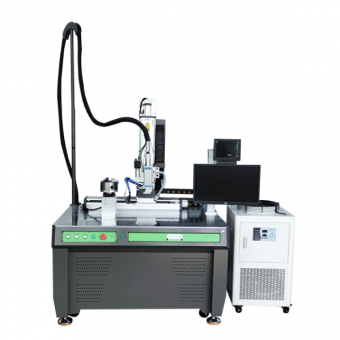

5V 30A 128 Channel Prismatic Cell Capacity Testing Machine Battery Testing and Grading Device

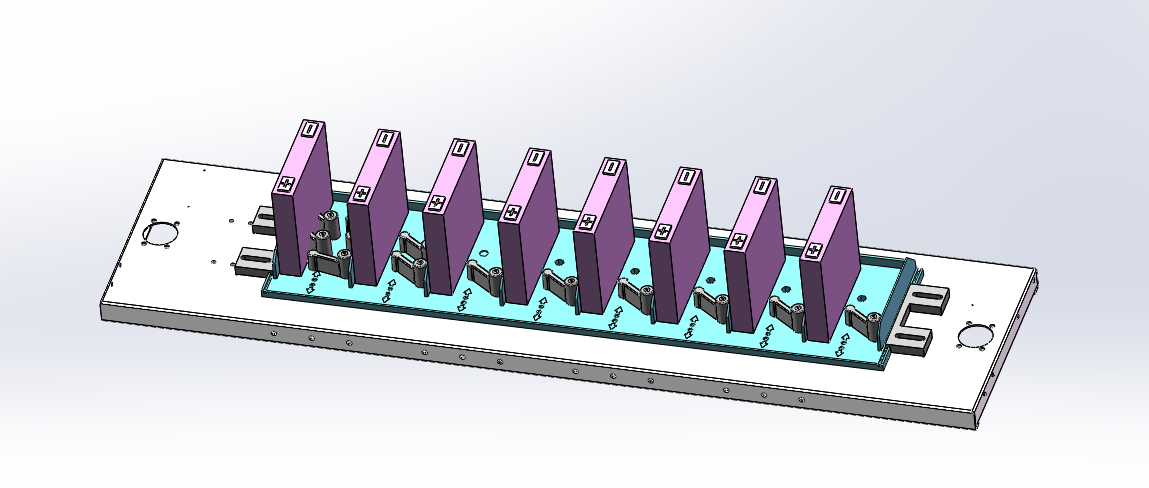

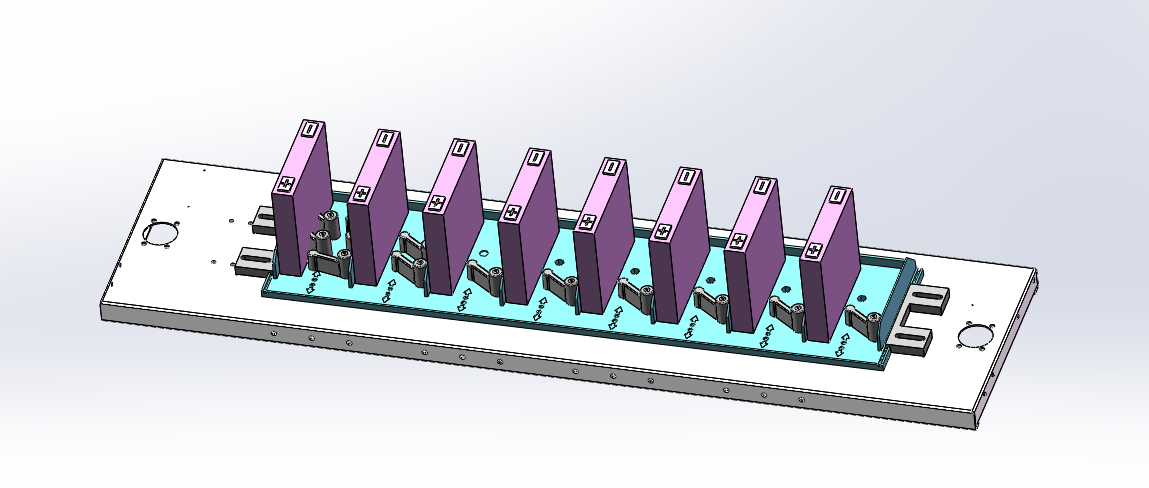

Ⅰ、Model No. and structure:

Model No.:TMAX-EF128-30k;

Equipment structure: The fixture adopts an overall automatic downward pressure design, and the batteries are placed on both sides

Machine size reference(mm):L2130mm*W700mm*H2020mm

Note: The positive and negative fixtures are designed using a pneumatic overall pressing method, with a maximum compatible distance of 150mm and a minimum distance of 45mm between the positive and negative electrode. The maximum height of compatible batteries is 220mm.

Note: The center distance between batteries is 78.5MM.

Note: The fixture adopts an automatic cylinder pressing and opening method, which saves energy and improves efficiency.

Fixture frame size parameters

|

Item

|

Specification

|

|

Fixture type

|

True four wire method multi needle clamp with adjustable spacing between positive and negative electrodes.

|

|

Tray height spacing

|

270MM

|

|

Minimum floor height above ground

|

270MM

|

|

The highest level above the ground

|

1620MM

|

|

Center distance between fixtures

|

78.5MM

|

|

Compatible battery height

|

50-220MM

|

Ⅱ、Main functions of the device

*Adopting modular manufacturing, with strong universality and easy maintenance.

*Adopting the four wire method for measurement, improving high testing accuracy.

*Each battery channel has a completely independent constant current and voltage source, and the self formed circuit does not affect each other.

*The equipment adopts the control method of sending the entire process.

*The sampling speed is fast, and the entire cabinet inspection time is ≤ 6s.

*Complete Windows platform software with powerful functions, user-friendly human-machine interface, and simple operation. The upper computer can set up to 32 steps and 256 cycles, and each formation step can have four optional attributes: constant current charging, constant voltage charging, constant current discharge, and sleep.

*Capable of real-time drawing of dynamic curves of each battery's formation and capacity division process, including voltage/time curve, current/time curve, capacity/time curve, energy/time curve, capacity/voltage curve, and other functional menus.

*LED indicator lights are used to indicate the working status of the battery.

*Communication method: RS485/WIFI.

*Each upper computer can monitor up to 10 devices.

*Equipped with data power-off protection function, it can continue to operate when there is a call.

*The software has the functions of editing and modifying the files in the process library, creating new monitoring, opening, closing documents, printing, and setting functions.

Ⅲ、Specification

|

ITEM

|

TMAX-EF128-30K

|

|

Channel

|

128 channel

|

|

Charging/discharging current range(mA)

|

200~30000

|

|

Current measurement accuracy

|

±0.05%FS+0.05%RD

|

|

Current resolution(mA)

|

1

|

|

Voltage measurement range(mV)

|

0~5000

|

|

Charging voltage range(mV)

|

0~4500

|

|

Discharge voltage range(mV)

|

1800~4500

|

|

Voltage measurement accuracy

|

±0.05%FS+0.05%RD

|

|

Voltage resolution(mV)

|

0.1

|

|

Time measurement range and accuracy

|

999min/step,accuracy:±0.1%

|

|

Equipment calibration method

|

Software digital calibration

|

|

Calibration cycle

|

6 months

|

|

Work step content

|

Constant current charging, constant current constant voltage charging, constant current discharge, quiescent state

|

|

Work step end conditions

|

Current, voltage, time, capacity

|

|

Maximum number of steps set

|

32

|

|

Maximum cycle set number

|

256

|

|

Curve display

|

Charge discharge current curve, charge discharge voltage curve, capacity curve

|

|

Capacity sharing method

|

Capacity grading, time grading, capacity+curve grading, time+curve grading, capacity+voltage grading, fixed point voltage grading

|

|

Protection method

|

Over current, under current, over voltage, under voltage, over capacity, and leakage current, with dual protection of hardware and software for charging over voltage/discharging under voltage

|

|

data statistics

|

The open circuit voltage, average voltage, working time, current, capacity, and platform capacity of each battery at each step; Detailed curves and data for each step; Count the number of batteries in each capacity segment, etc

|

|

Inspection speed(s)

|

≤6

|

|

Communication method

|

RS485/WIFI

|

|

Battery scanning function

|

Support barcode scanning, capable of scanning one-dimensional and two-dimensional codes, including sequential scanning and channel skip scanning, and binding with device channel information for easy traceability in the future. (According to the barcode method of the user, the wireless scanning gun is provided by Party B)

|

|

Data processing function

|

1. Local data

Save detailed data of the device's operation locally, without deleting it. Follow the process of saving one file per run, and the data file can be copied to other computers for viewing.

Save the result data of the device's work locally, without deleting it. Save a CSV file for each process run, and only save the end data of each step in the result data file.

2. Server data

If a data server is configured, the result data can be uploaded to the number of servers

According to the database, the retention period can be set according to customer requirements, and this CSV file is the standard

Database format, which can be integrated with the MES system

|

|

Number of controllable devices per computer

|

1~10

|

|

Frame size (mm) (reference)

|

L2130mm*W700mm*H2020mm

|

|

Total power of equipment(KW)

|

≤34

|

|

Power efficiency

|

The charging and discharging power supply adopts energy-saving power supply, and the battery discharge energy is fed back to the power grid.

The maximum efficiency of power charging output shall not be less than 70%, and the maximum efficiency of power recycling shall not be less than 65%.

|

|

Equipment stability

|

The equipment has good long-term stability and accuracy calibration ensures that it does not exceed the agreed accuracy control range within 6 months.

|

|

Working power supply

|

3 phase,AC380V±10% 50Hz

|

|

Air switch

|

Three phase four wire air switch with zero line leakage protection function

|

|

Working compressed air

|

Not less than0.5MPa/air inlet:10mm

|

Ⅳ、AC/DC Bidirectional power supply

The equipment adopts energy-saving AC/DC bidirectional power supply, with high charging efficiency and feedback of battery discharge energy to the power grid.As shown in the above figure, a portion of the battery discharge energy is used internally by the power supply itself, another portion is used by other charging devices, and the remaining portion is fed back to the power grid for use by other devices.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported